Guindy, Chennai, Tamil Nadu

- GST NO. : 33AAICK2306A1ZA

Analysis Services

Leading Exporters, Wholesaler of Finite Element Analysis Services, Pipe Flexibility Analysis Services and Piping Stress Analysis Services from Chennai.

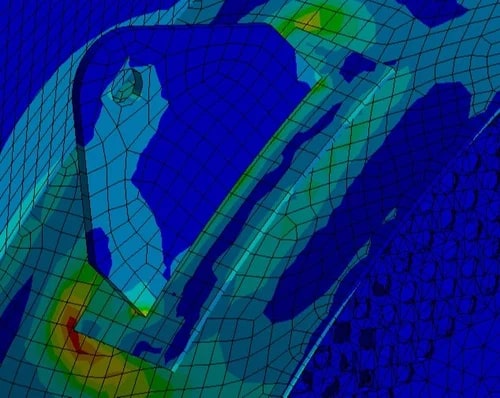

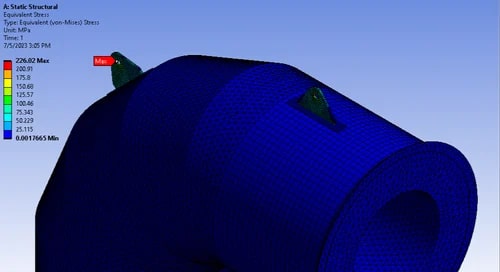

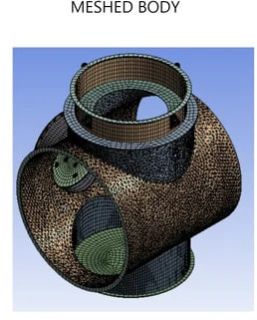

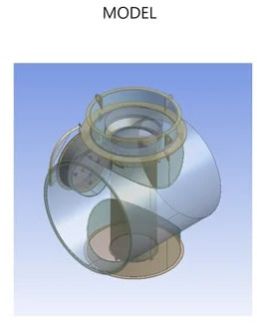

Finite Element Analysis (FEA) Services provide advanced computational solutions to evaluate the structural, thermal, and dynamic performance of components and systems. These services help identify stress points, deformation, vibration, and failure risks under various operating conditions. Using cutting-edge FEA software, engineers create detailed simulations to optimize designs and ensure compliance with industry standards. Applications span across industries, including aerospace, automotive, civil engineering, and manufacturing. FEA Services enhance product reliability, reduce prototyping costs, and accelerate development cycles. From material behavior analysis to complex assemblies, these services deliver precise insights, enabling innovative, efficient, and safe design solutions tailored to specific requirements.

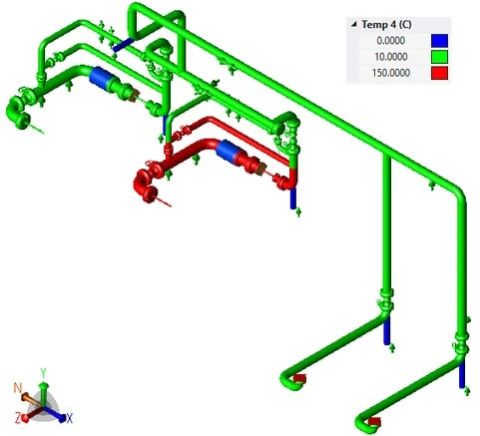

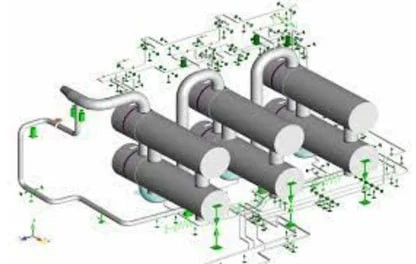

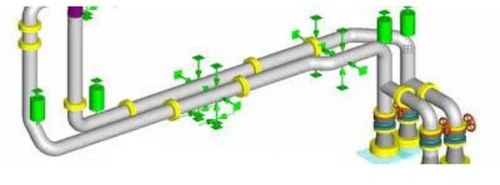

A pipe stress analysis (thermal flexibility analysis) predicts stresses in piping and loads on equipment resulting from thermal gradients, thermal transients, weights, pressure, and bolt-up strain. This study is typically required for piping that experiences high temperature fluctuations, or for long pipe runs such as hot piping to coolers or headers. Cases where equipment is sensitive to external loads may also require a pipe stress analysis.

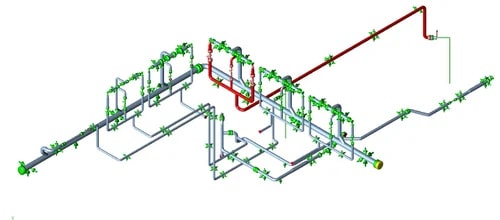

The study methodology becomes more complicated for piping systems in vibratory service. As discussed below, the design must address conflicting requirements between the pipe stress analysis (where flexibility is desired) versus the mechanical vibration analysis (which requires stiff supports). Methods are available to manage this conflict and create an optimal piping design.

Piping Stress Analysis Services ensure the safety, reliability, and efficiency of piping systems used in industries such as oil and gas, power plants, chemical processing, and manufacturing. These services evaluate piping systems under various operating conditions, including pressure, temperature, and external loads, to identify potential stress points and ensure compliance with industry standards like ASME and ANSI. Using advanced simulation software, engineers assess thermal expansion, vibration, and seismic impacts to optimize system design. The analysis helps prevent failures, reduce maintenance costs, and extend the lifespan of the piping infrastructure. Piping Stress Analysis Services deliver tailored, efficient solutions for complex systems.